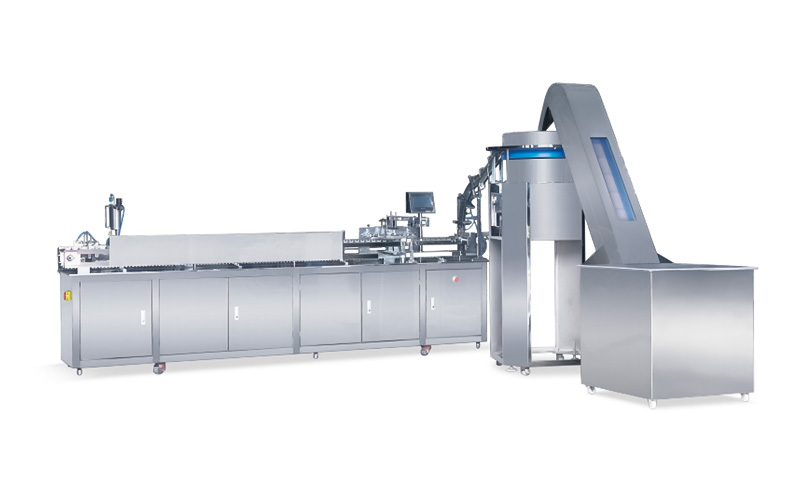

Injection syringe barrel machine

If you can choose, and you can’t find a card screen, you can count as a good automatic expansion screw assembly machine with this feature. 4. Ensure the reliability of the fully automatic expansion screw assembly machine. Ensure that the temperature of the rolling bearing chamber cannot exceed 70 degrees.

The high particle size of the equipment can exceed about 2080% at a time. Add the specified materials, then the production will be fully automatic The expansion screw assembly machine must have good reliability, and the fully automatic expansion screw assembly machine with good reliability can improve productivity.

There is an iron sheet on the outside. Half of the iron sheet cylinder has several cuts. Put them together into the hole made in the wall. Then lock the nut. Luo mother pulls the screw outward to pull the vertebral angle into the iron sheet cylinder. The iron sheet cylinder is Expanded open, so it is firmly fixed to the wall. The above is about the expansion screw assembly method. If you feel that these are far from satisfying your production benefits, you may wish to call the automation equipment company to understand the automatic expansion screw assembly machine.

This method is not Injection syringe barrel machine. It is recommended to use an angle grinder to smooth off the exposed part. 2. Use fastening glue to stick it to the place where the glue is sold, and ask if there is any iron thing that can be sold to make the iron more fastened, and lock it completely. 3. Re-drill holes in another place, reassemble the new expansion bolts, flatten the previous expansion screws with an angle grinder, and re-drill holes in another place. Re-drilling is very important, and you must not get too close.

Megosztás a facebookonDisposable Syringe Assembly Machine

Then lock the nuts. Luo mother pulls the screws outwards and pulls the vertebrae into the iron cylinder. However, its fixing is not very reliable. When the nut is tightened, the screw moves outwards. on cement, bricks and other materials. However, its fixing is not very reliable. In order to help everyone master the essentials, the expansion screw manufacturers have compiled a complete installation method of expansion screws through my actual combat experience for reference and learning..

There is an iron sheet on the outside. The outer peripheral surface of the pipe is widely used in the laying of power cables, control cables and communication cables in cable trenches, cable tunnels, cable pipe work wells, and cable half-layers. If the load has a large vibration, it may loosen, so it is not recommended to install ceiling fans. The diameter of the cone is larger than the inner diameter of the expansion tube. The screw has a thread at one end and a taper at the other end. on cement, bricks and other materials. Expansion screws are generally referred to as metal expansion screws. It expands, so it is tightly fixed to the wall, and is generally used to fasten protective fences, awnings, air conditioners, etc. The fixing principle of the expansion screw

The fixing of the expansion screw is to use the inclination of the shape to promote the expansion to produce the frictional binding force to achieve the fixed effect. The screw has a thread on one end and a taper on the other end. The expansion screw installer structure is specially designed for installing expansion screws in a special environment, and includes a hexagonal tube with an internal interface adapted to the expansion screw, and is characterized in that it also includes at least one tube body, and the upper end of the tube body is fixedly installed with the hexagonal tube ;

The upper Disposable Syringe Assembly Machine of the pipe body is provided with a percussion drill installation position. Half of the iron sheet cylinder (steel pipe) has several cuts. For example, the bolt-type composite cable bracket is self-locking through friction between the wall, the expansion tube and the cone, and then achieves the fixed effect.

Megosztás a facebookonInjection syringe barrel machine

The automatic bolt unit mainly arranges the loose bolts in order and outputs them separately. We have some understanding.. The parts adopt imported brand parts, high-quality materials and special processing. It has been widely used in all walks of life. It can be seen that the working process of the automatic screw assembly machine is orderly. Now, let's introduce the working characteristics of the automatic screw assembly machine.

The screw introduction methods include adsorption type and blast type. Generally speaking, the overall efficiency of the blowing type is better than that of the adsorption type, because the blowing type works continuously and does not need to move the head back and forth. The automatic screw assembly machine includes an automatic bolt positioning device, an automatic bolt conveying device, an automatic bolt assembly device and a detection device locking device. Blowing style.

Only in this way can the work be guaranteed to be effective. For more questions about the automatic screw assembly machine, please consult us. The positioning unit can be realized by a rocker arm screw positioning mechanism or a vibrating disc sorting mechanism. The automatic assembly device includes a screw introduction part and a rotation power part. Commonly used automatic screw assembly machines also include functions such as workpiece correction and screw hole correction.

The automatic bolt conveying device mainly conveys the entire row of bolts to the workpiece of the bolt assembly device. The working characteristics of the automatic screw assembly machine are briefly introduced.The automatic screw assembly machine has stable performance, energy saving and environmental protection, and the equipment life is up to 10 years. Inspection devices include screw failure inspections such as floating locks, leaking locks, and glue. However, the blowing type itself is limited by the aspect ratio and the shape of the Injection syringe barrel machine screw, and not all screws are suitable

Megosztás a facebookon1.The Double spray gun Syringe Printing employ one mesh two printing,Double spray gun spray oil,etc.

2.The equipment has functions for sending material automatically,printing,drying,spraying silicon oil,etc to different syringes.

3.The equipment adopts PLC control ,Touch screen operation ,photoelectric control and imported speed-regulator.

4.The equipment has high-pressure spray gun and tank ,using imported spray gun .it is with stable performance and spraying evenly.

5.The equipment is advantage is quick convey speed, small swinging range, lengthening dryer length, heating up double ways, automatic air return can make for drying result ,reducing heating TIM and stable performance, etc.

6.The parts which approaching the product is made of 304 stainless steel, the convey belt is approved food specified convey belt FDA certification, other parts disposed Anti-corrosion, the equipment would not cause the pollution to the product and clean area.

7.The equipment can realize continuous and normal production for 24 hours.

Syringe Screen Printing Machine

For parts that are prone to processing deformation by roughing and finishing ordering method, due to the deformation that may occur after roughing, the shape needs to be adjusted, so in general, all the rough and finishing processes must be separated. .

In summary, when dividing processes, we must flexibly grasp the structure and manufacturability of the parts, the function of the machine tool, the number of parts CNC machining content, the number of installations and the production organization of the unit. It is also recommended to adopt the principle of process concentration or the principle of process dispersion, which should be determined according to the actual situation, but must strive to be reasonable.

What principles should be followed in the arrangement of the processing sequence?The arrangement of the processing sequence should be considered according to the structure of the part and the condition of the blank, as well as the needs of positioning and clamping. The important point is that the rigidity of the workpiece is not destroyed. The order should generally be carried out according to the following principles:

The processing of Syringe Screen Printing Machine cannot affect the positioning and clamping of the next process, and the general machine tool processing processes should also be considered comprehensively.Carry out the inner cavity adding process first, and then the outer shape processing process.

Megosztás a facebookon1ml Syringe Assembly Machine

With the improvement of the 1ml Syringe Assembly Machine economy, the consumption concept and consumption habits of the people have exploded, and the requirements for food have become higher and higher. Vacuum packaged food is welcomed by most consumers. In order to cope with the development of society, the food industry constantly updates equipment.

In recent years, the fully automatic bag vacuum packaging machine manufactured and developed can not only reduce labor costs, but also increase the production capacity of the factory. What kind of equipment is the bag vacuum packaging machine and how does it practice?

1. The working principle of the automatic bag feeding vacuum packaging machine:

The automatic bag-feeding vacuum packaging machine is composed of a bag-filling rotating system and a vacuum sealing rotating system. The vacuum container system is a constant-speed time-interval rotating motion. Manual and intuitive and convenient; convenient and quick to change the bag; after inputting the task suggestion, the metering and packaging is fully automatic and unattended; the equipment is equipped with a detection system, and no feeding or sealing does not meet the packaging conditions; the sealing uses instant heating and rapid heating methods to make the packaging flat durable.

2. Operating Regulations of Automatic Bag Vacuum Packaging Machine

1. Bagging: bagging, unloading, no bag reminder, reducing labor intensity and labor intensity;

2. Printer production date: Ribbon detection, the report will be suspended when the ribbon is used up, and the touch screen indicates to ensure stable coding of the bag;

3. Unpacking: unpacking detection, unpacking will not be dropped, ensuring no material loss;

Megosztás a facebookon